All buildings must be designed to resist wind forces, and this is especially critical for buildings that are tall, unusually shaped, or located in hurricane-prone areas. Most building codes in the US, including the International Building Code and the Florida Building Code, adopt ASCE 7 “Minimum Design Loads for Buildings and Other Structures” for wind design. ASCE 7 is updated about every six years based on the most current wind research and informed by studies of damage caused by recent high wind events. This provides the tools for engineers to calculate wind pressures and loads for use in the design of all types of buildings and other structures.

Engineers often want more accurate wind pressures and loads to reflect project-specific conditions. Wind tunnel testing provides more accurate design information than can be obtained from the code by taking into account specific building architecture and the effects of its surroundings. This allows the designer to maximize design efficiency while ensuring reliability targets are met. Building codes recognize the advantages that wind tunnel testing provides and allows designers to use those results in lieu of the calculated pressures. Pennoni’s structural engineers generally recommend wind tunnel testing to building owners and developers when a proposed structure is more than 10 stories in height or has an unusual shape.

Benefits to wind tunnel testing include:

- A reduction in design wind pressures. The design pressures are normally lower than those required by ASCE 7 over large areas of the building envelope, resulting in cost savings to the exterior doors and windows, exterior walls, roofing, shear walls, and foundations.

- Identification of potential wind-induced building motions that may be experienced (unfavorably) by building occupants.

- Identify potentially undesirable winds in public and other occupied areas in and around a development. Wind flow around a building can be uncomfortable to occupants in open areas such as plaza decks and balconies.

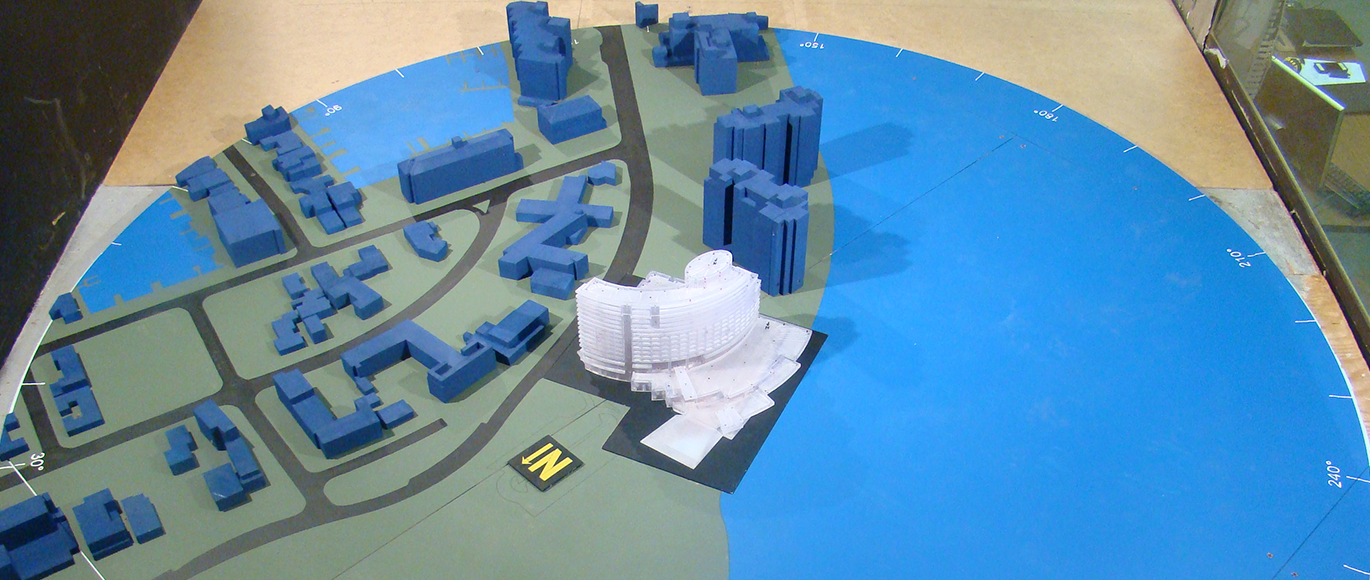

To conduct a wind tunnel test of a building, specialized companies build an instrumented scale model of the proposed building and all surrounding structures on a turntable in a boundary layer wind tunnel. The boundary layer wind tunnel simulates the characteristics of the natural wind and the turntable allows the model to be rotated to assess a full range of incident wind directions. Sensors connected to the test building model allow experts to determine both local design pressures for the building envelope and overall wind loads and responses for structural design.

CPP Wind Engineering

Most of the wind tunnel testing on Pennoni’s projects have been done by CPP Wind Engineering in Windsor, CO where their buildings group is led by Roy Denoon, PhD. CPP has been a valuable consultant to Pennoni for many years. Roy has been involved in wind tunnel testing for 30 years. He has worked on many of the world’s most challenging structural projects from two Olympic stadiums to some of the world’s tallest buildings. In 2019, in recognition of his contributions to tall building design, he was made a Fellow of the Council on Tall Buildings and Urban Habitat, the first wind engineer to receive this accolade. He is a member of the ASCE 7 wind loads subcommittee and was a primary author of the recently published ASCE Pre-standard on Performance-Based Wind Design.

One example of a successful wind tunnel test is the DeMarcay Condominiums. Pennoni is the structural engineer-of-record for this 18 story residential building in downtown Sarasota, FL. It has a very small footprint and a plaza deck and swimming pool on the roof. CPP constructed a 1:240 scale model of the tower and surroundings for testing in one of its newest boundary layer wind tunnels. Testing was conducted primarily to determine wind-induced structural loading and responses and local pressures on the building envelope. Further testing was also used to investigate wind comfort at ground level and on elevated balconies, terraces, and outdoor amenity areas.

The wind tunnel testing of the DeMarcay Condominium tower showed structural wind loads in the critical direction that were around 80% of those that would be calculated by code approaches. Similarly, the local pressures were below code values over the vast majority of the building envelope with the exception of one small area at the lower floors where the tested loads were higher than the code loads. Adoption of code-based pressures in this small area could have resulted in localized damage to the building cladding under hurricane wind forces.

Other examples of buildings designed by engineers at Pennoni’s Clearwater office that have benefitted from wind tunnel testing include:

- Opal Sands Hotel, Clearwater Beach, FL – A 15 story luxury hotel with a curvilinear shape located directly on the waterfront. The wind tunnel test performed by CPP provided Pennoni’s designers with accurate pressures that accounted for acceleration of wind flow around the curved wall surfaces.

- Bliss Condominiums, Petersburg, FL – An 18 story residential building in downtown St. Petersburg. The results of the wind tunnel test performed by CPP included the effects of hurricane wind flow through the downtown area and around all the existing buildings surrounding the new Bliss Condominium tower.

- Blue Lotus Condominiums, Petersburg, FL – Originally designed as a 35 story residential tower with a very thin floor plan width located in an urban setting. Wind tunnel testing concluded that under gusting hurricane force wind loads, occupants may feel slight movement due to acceleration of the building. Pennoni’s engineers worked closely with CPP Wind Engineering to add mass to the building to eliminate the problem.

- 1991 Main Apartments, Sarasota, FL – Two 10 story residential buildings in downtown Sarasota that are currently in design and awaiting the results of wind tunnel testing. The results will accurately reflect wind pressures and allow the owner to use a preferred window system.

For more information on Pennoni’s High Wind Design Experience, watch our video:

Mike McCarthy serves as Vice President and his engineering expertise includes more than 40 years of structural analysis, design and construction of both new and renovation projects throughout the country and internationally. Mike is a recognized expert in the design of buildings located in high wind hurricane zones and flood hazard areas.

For more information, contact Mike McCarthy at mmcarthy@pennoni.com.